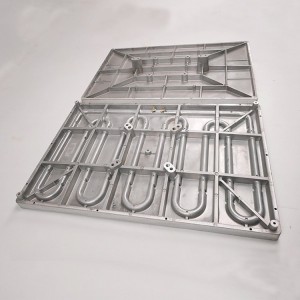

Cast aluminum heating plate is a metal casting heater is a tubular electric heating element as the heating body, and bent forming, into the mold with high-quality metal alloy material as the shell to centrifugal casting into a variety of shapes, there are round, flat, right Angle, air cooled, water cooled and other special shapes. After finishing, it can be closely fitted with the heated body, and the surface load of cast aluminum can reach 2.5-4.5w/cm2, and the high working temperature is between 400-500℃; The surface load of cast copper can reach 3.5-5.0w/cm2, and the high working temperature is between 600-700℃; The surface load of cast iron can reach 4.5-6.0w/cm2, and the high working temperature is between 800-850℃.

The hot plate for het press is an efficient and uniform heat division heater, and the thermal conductivity of the metal alloy ensures the uniform temperature of the hot surface and eliminates the hot and cold spots of the equipment. It has the advantages of long life, good insulation performance, strong mechanical properties, corrosion resistance, magnetic field resistance and so on. The heat preservation device is added to the external heat dissipation surface, and the infrared ray is sintered on the internal heat dissipation surface, which can save 35% of electricity.

1. Material: aluminum ingots +heating tube

2. Shape: customized

3. Voltage: 110V or 230V

4. Size: 380*380mm,400*500mm,400*600mm,600*800mm,etc.

***we aslo have some custom big size heater,like 1000*1200mm,1000*1500mm,etc.

5. Power: standard,if the quantity more than 100sets,power can be designed

6. Package: packed in the carton

7. different size the weight is different.

1. the working voltage shall not exceed 10% of the rated value; The relative humidity of the air is not more than 95%, no explosive and corrosive gases.

2. the wiring part is placed outside the heating layer and insulation layer, and the shell should be effectively grounded; Avoid contact with corrosive, explosive media and water; The wiring should be able to withstand the temperature and heating load of the wiring part for a long time, and the fastening of the wiring screws should avoid excessive force.

3. the die-casting aluminum heating plate should be placed in a dry place, if the insulation resistance is less than 1mω due to long-term placement, it can be baked in the oven at about 200 degrees Celsius for 5-6 hours, you can return to normal. Or reduce the voltage and power heating until the insulation resistance is restored.

4. the aluminum heat plate should be positioned and fixed, the effective heating area must be closely fitted with the heated body, and air burning is strictly prohibited.

Before the inquiry,pls send us below specs:

1. Sending us the drawing or real picture;

2. Heater size,power and voltage;

3. Any special requirements of heater.