| Plate size | 380*380mm,380*450mm,400*500mm,400*600mm,600*800mm,etc |

| Power | customized |

| Voltage | 110V,220V |

| MOQ | 3 sets |

|

1.Use condition: environment temperature -20-+300C, Relative temperature <80% 2.Leakage current:<0.5MA 3.Insulation resistance:=100MΩ 4.Ground resistance:<0.1 5.Voltage resistance: no electric breakdown for 1 minute under 1500V 6.Temperature endurance:450°C 7.Power deviation:+5%-10% Note: Other models are available according to your specificationsower will manufacture it according to customer require. |

|

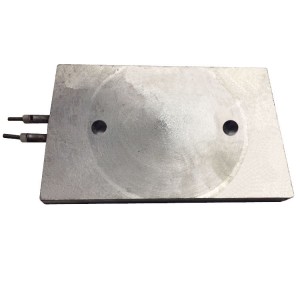

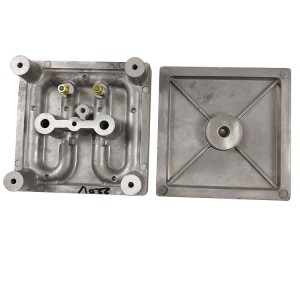

Cast aluminum electric heating plate is a metal casting heater is a tubular electric heating element as the heating body, and bent forming, into the mold with high-quality metal alloy material as the shell to centrifugal casting into a variety of shapes, there are round, flat, right Angle, air cooled, water cooled and other special shapes. After finishing, it can be closely fitted with the heated body, and the surface load of cast aluminum can reach 2.5-4.5w/cm2, and the working temperature is within 400℃;

Cast aluminum heating plate is widely used in plastic machinery, mold, cable machinery, alloy die-casting machine, pipeline, chemical, rubber, oil and other equipment and suitable for clothing, plastics and other industrial products printing, hot stamping, drying.

1, the working voltage shall not exceed 10% of the rated value; The relative humidity of the air is not more than 95%, no explosive and corrosive gases.

2, the wiring part is placed outside the heating layer and insulation layer, and the shell should be effectively grounded; Avoid contact with corrosive, explosive media and water; The wiring should be able to withstand the temperature and heating load of the wiring part for a long time, and the fastening of the wiring screws should avoid excessive force.

3, the metal casting heater should be placed in a dry place, if the long-term placement, insulation resistance is less than 1MΩ, can be baked in the oven at about 200 degrees Celsius for 5-6 hours, you can return to normal. Or reduce the voltage and power heating until the insulation resistance is restored.

4, the metal casting heater should be positioned and fixed, the effective heating area must be closely fitted with the heated body, and air burning is strictly prohibited. When dust or pollutants are found on the surface, they should be cleaned and reused in time to avoid the shadow and heat dissipation and shorten the service life.

5. Magnesium oxide powder at the outlet end of the electric heat pipe should be avoided by pollutants and water infiltration in the use place to prevent the occurrence of leakage accidents.