| Main Material | Silicone(V0,V1) and imported silicone V0 options |

| Temperature Rating | 482°F(250°C)maximum operating |

| Thickness | normally 0.03 inch/ 0.75mm (Single-Ply),0.06 inch / 1.5mm(Dual-Ply),support custom |

| Voltage | Any AC or DC (3V-660V), or 3phase |

| Power density | Normal 0.03-0.8watts per square centimeter,maximum 3W per square centimeter |

| Power lead wire | Silicone rubber, SJ Power Cord, or Teflon insulated stranded wire options,usually 100cm length or as requested |

| Attachment | Hooks, lacing eyelets, Temperature control(Thermostat), |

| Description | 1. Silicon Rubber Heating Pad/Sheet has advantages of thinness, lightness, sticky and flexibility. |

| 2. It can improve heat transfer, accelerate warming and decrease power under the process of operation. | |

| 3. They are heating fast and thermal conversion efficiency high. |

1. The thinness, lightness, and flexibility of silicone rubber heaters are advantages;

2. When in use, the silicone rubber heater can increase heat transfer, hasten warming, and use less power;

3. The dimension of heaters is stabilized using silicone rubber reinforced with fiberglass;

4. The maximum wattage for the silicone rubber heater is 1 w/cm2;

5. The silicone rubber heaters are customizable in terms of size and shape.

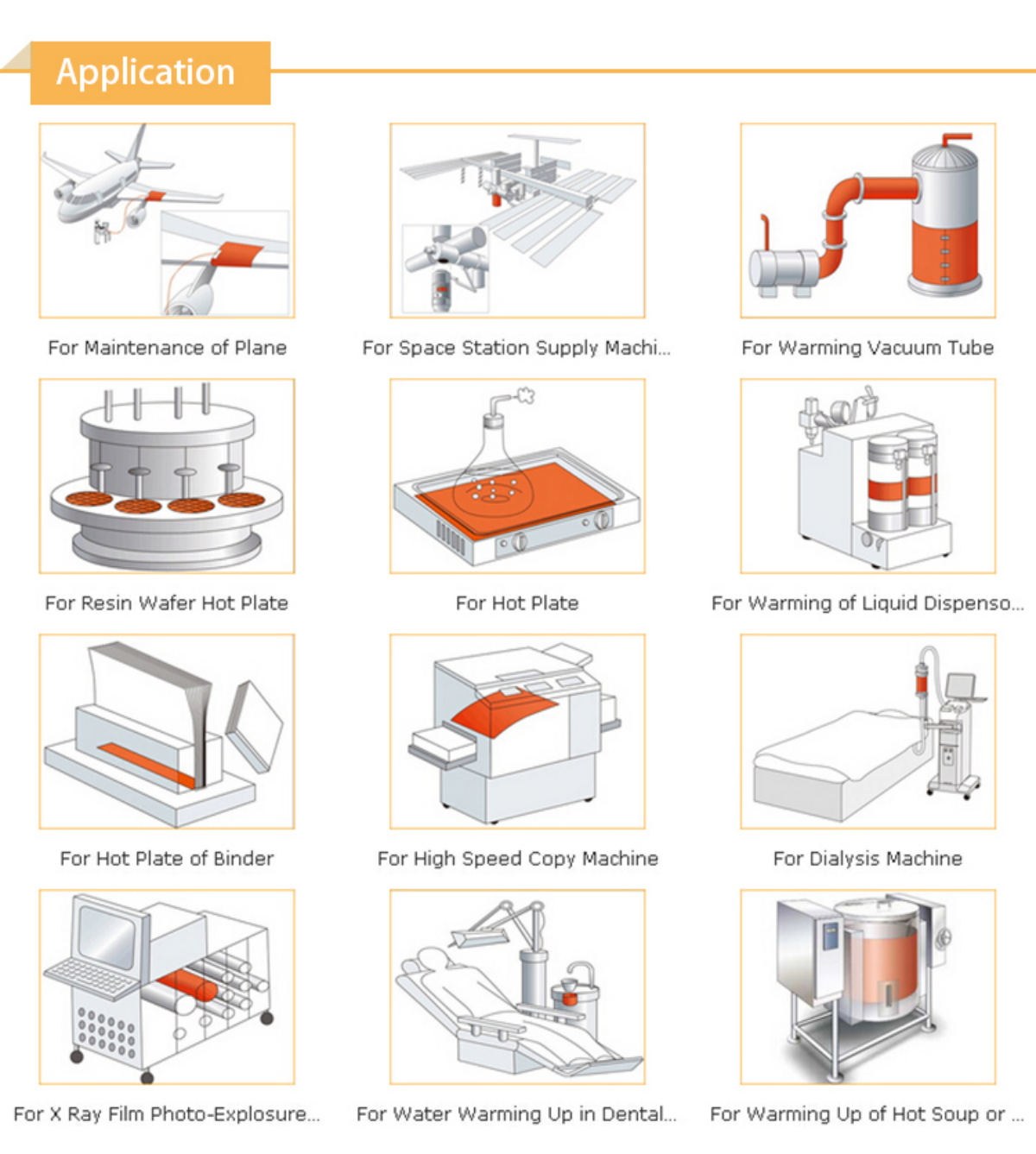

Thermal transfer apparatus

Prevent condensation in instrument or motor cabinets.

Preventing freeze or condensation in housings that house electrical equipment, such as automatic teller machines, temperature control panels, gas or liquid control valve housings, and traffic signal boxes.

Composite bonding techniques

Aerospace industry and airplane engine warmers

Drums, other vessels, viscosity regulation, and storage of asphalt

medical devices such test tube heaters, medical respirators, and blood analyzers

Curing of laminated plastic

Computer accessories including laser printers and copying equipment