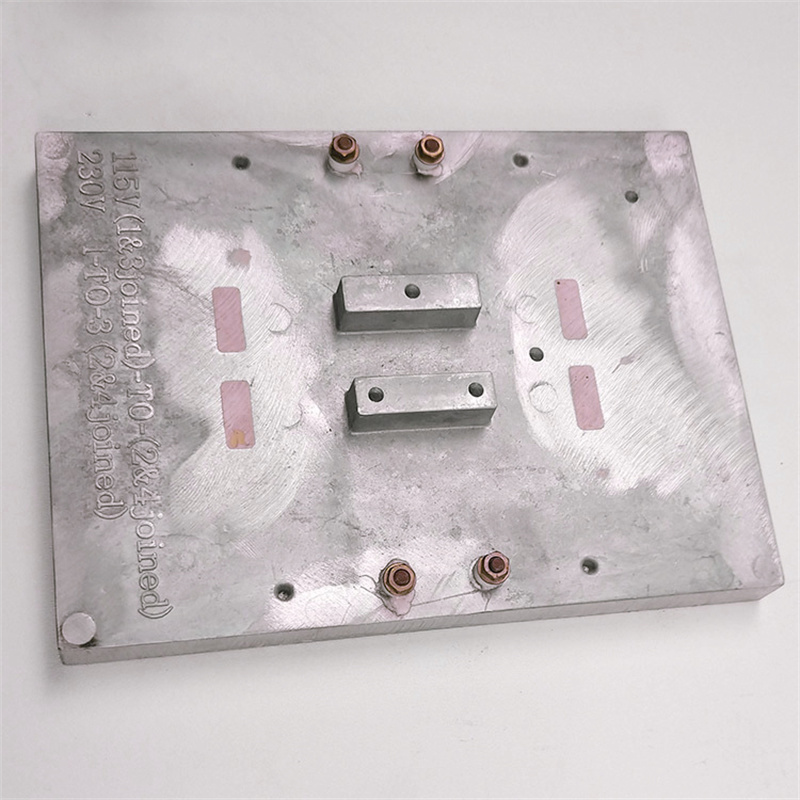

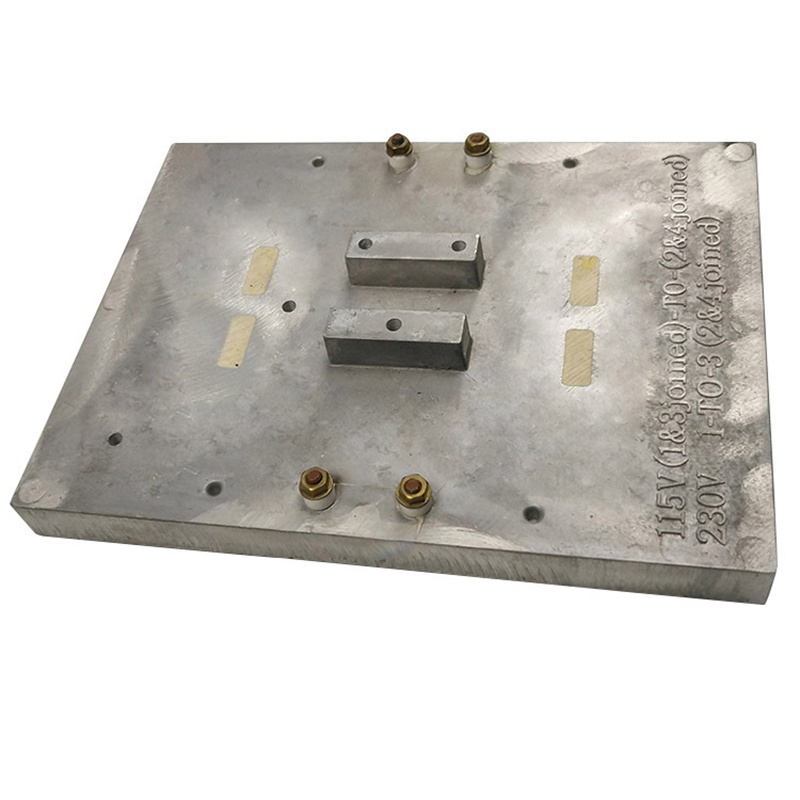

Characteristics of aluminum plate electric heating plate

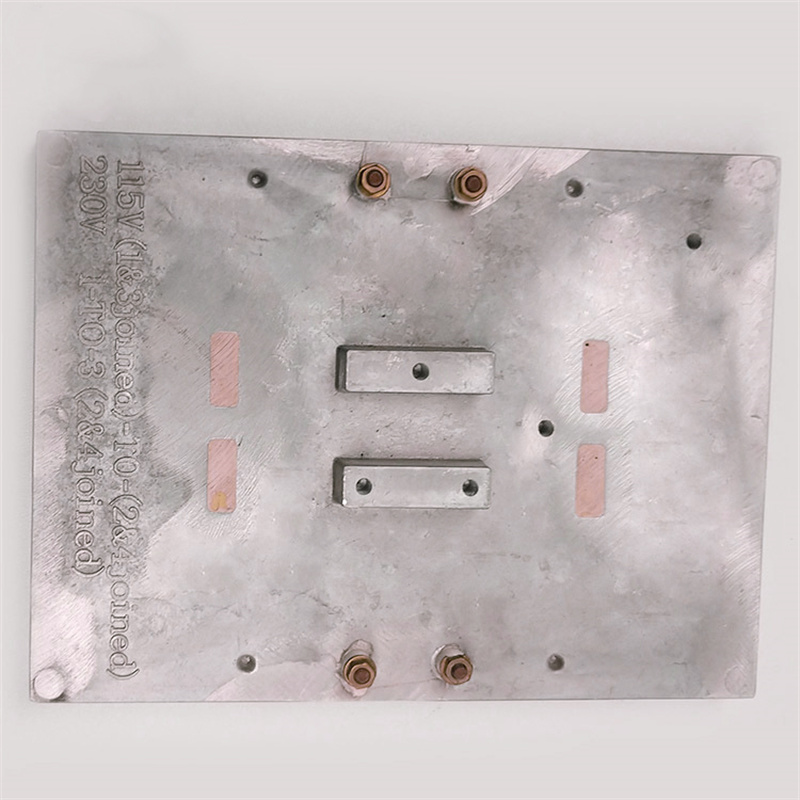

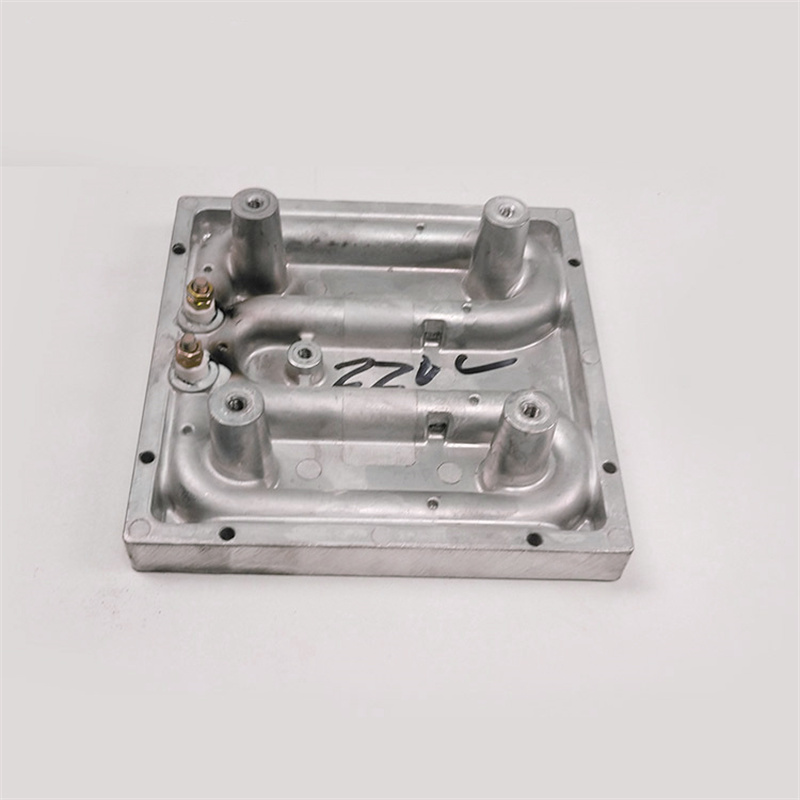

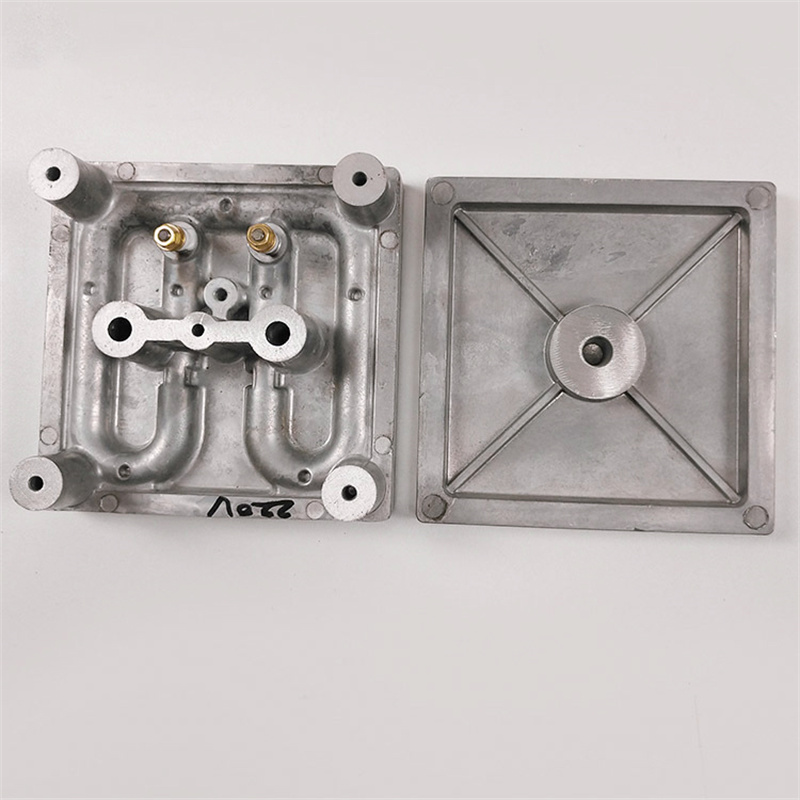

1. Uniform heat distribution, with good heat dissipation effect products for rigid plate, easy to install, with the face can be directly glued to the surface of the heated body.

2. High insulation performance, can withstand 2500VDC high voltage test, safe and secure to use, safety in line with national safety standards.

3. Aluminum plate electric heating plate using aluminum and silica gel for the base, aluminum plate has a good thermal conductivity, can better conduct heat to the required heating parts, silica gel has good shock resistance waterproof, voltage resistance and other properties, is one of the highest characteristics of the heating plate products;

4. Aluminum electric heating plates provide several benefits, including a minimal temperature difference, superior insulation and pressure resistance, moisture resistance, simplicity of manufacturing, and many other properties.

Aluminum plate electric heating plate has excellent anti-mechanical strength performance, excellent insulation and pressure resistance, moisture-proof, easy processing and other characteristics, small temperature difference, and many other characteristics, in the mechanical equipment, aerospace, military, new energy and other fields, to solve the many low temperature caused by the trouble.

In addition in the parts and mold heating, wood and paper industry, automotive industry, mold manufacturing, plastic industry, binding has also been popularly used.