Product Configuration

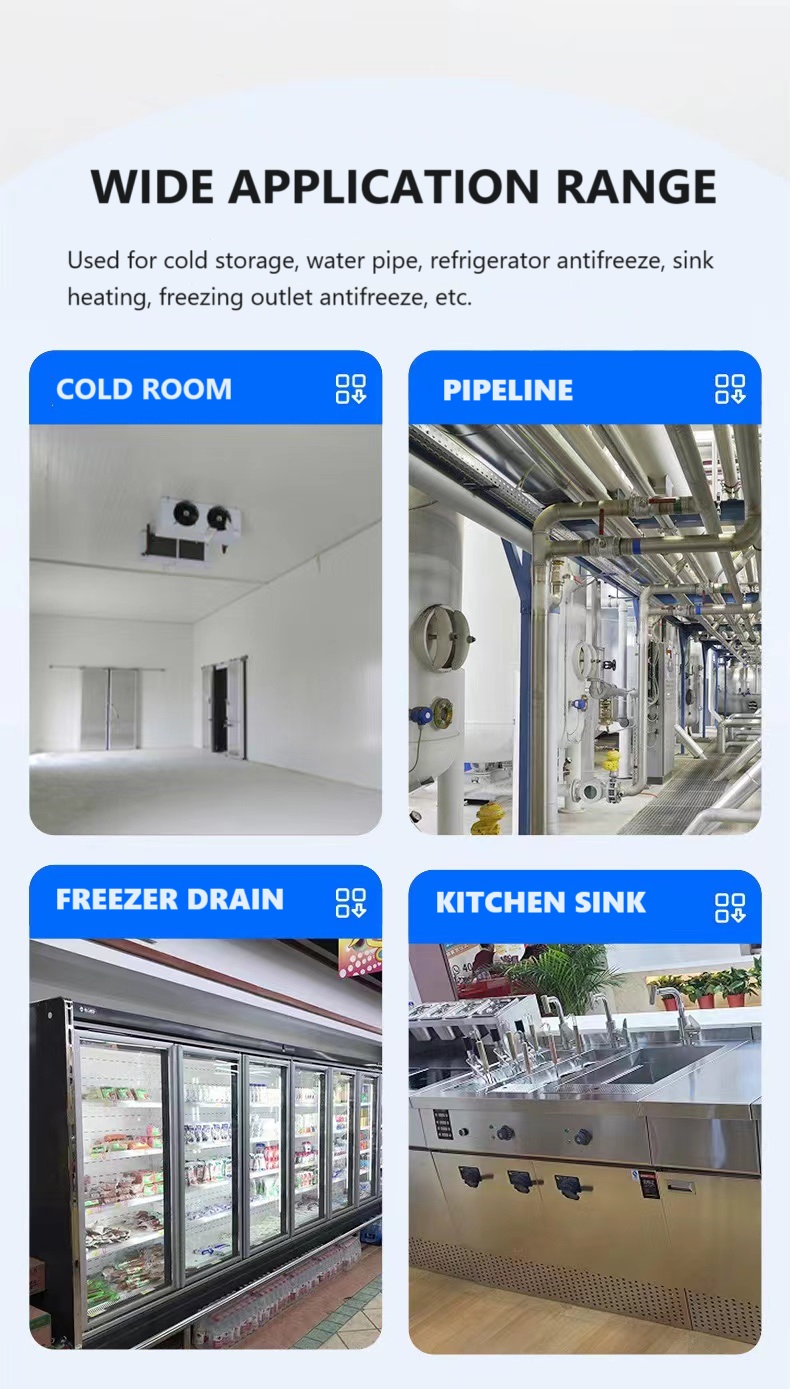

The freezer door frame heater is a specially designed heating element, widely used in refrigerators, freezers and other refrigeration equipment. The defrost door frame heater wire main function is to melt the frost layer formed on the surface of the evaporator through heating, thus ensuring the continuous and efficient operation of the refrigeration equipment. This braided door heating wire is usually made of nickel-chromium alloy, a material widely adopted due to its excellent corrosion resistance and electrical conductivity.

To further enhance its performance and safety, the surface of the defrost heating wire is usually covered with a layer of silicone rubber or PVC layer to provide good electrical insulation effect. In addition, a protective layer of glass fiber, stainless steel or aluminum is braided around the heating wire. The main purpose of door frame heater design is to prevent the surface of the heating wire from being damaged by external factors during installation and use, thereby avoiding potential problems such as short circuits.

Product Paramenters

| Porduct Name | Freezer Defrost Door Frame Heater Cable |

| Insulation Material | Silicone rubber |

| Wire diameter | 2.5mm,3.0mm,4.0mm,etc. |

| Heating length | customized |

| Lead wire length | 1000mm,or custom |

| Color | white,grey,red,blue,etc. |

| MOQ | 100pcs |

| Resistant voltage in water | 2,000V/min (normal water temperature) |

| Insulated resistance in water | 750MOhm |

| Use | silicone rubber heating wire |

| Certification | CE |

| Package | one heater with one bag |

|

The defrost door frame heater length,voltage and power can be customized as required.The wire diameter can be choosed 2.5mm,3.0mm,3.5mm,and 4.0mm.The wire surface can be braided firberglass,aluminum or stainless steel. The defrost wire heater heating part with lead wire connector can be seal with rubber head or double-wall shrinkable tube,you can choose according to your own use needs. |

|

Product Function

During the actual operation of a refrigerator, the evaporator, due to its extremely low temperature, causes water vapor in the air to condense on its surface and gradually form a frost layer. As time goes by, the thickness of the frost layer will continuously increase, which not only affects the heat exchange efficiency of the evaporator but may also lead to a decline in the cooling effect or even equipment failure. To address this issue, modern refrigerators are generally equipped with an automatic defrosting system. When the built-in sensor detects that the thickness of the frost layer exceeds the set threshold, the system will activate the aluminum braided defrost heating wire to perform a heating operation. At this point, the defrost door frame heater wire will generate sufficient heat to melt the frost layer into water, which is then drained out of the device through the drainage system. Once the frost layer is completely melted, the door frame heating wire will stop working, and the refrigerator will immediately return to its normal cooling state, continuing to provide users with a stable refrigeration or freezing environment.

Product Features

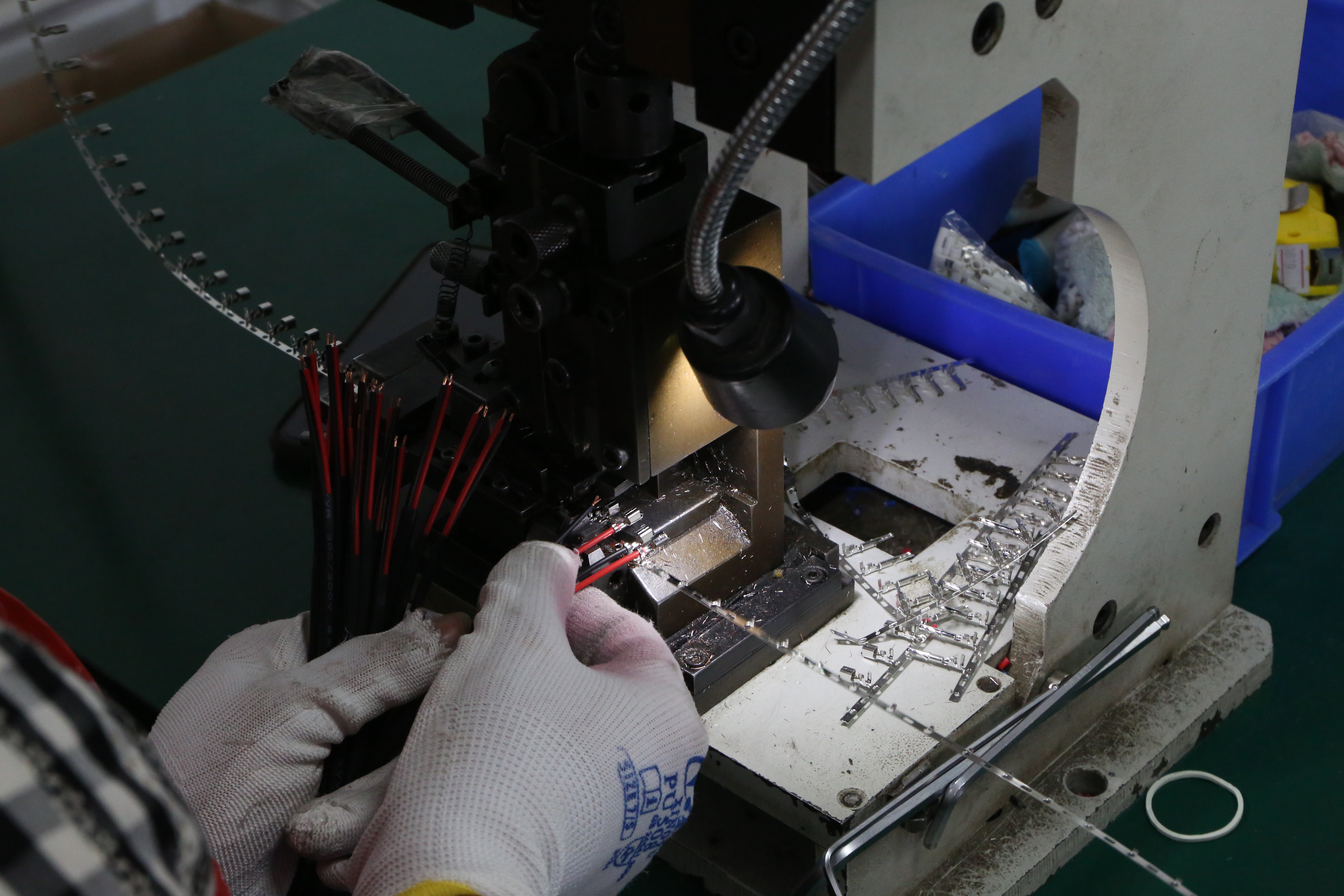

Factory Picture

Production Process

Service

Develop

received the products specs,drawing,and picture

Quotes

the manager feedback the inquiry in 1-2hours and send quotation

Samples

Free samples will be sent for check products quality before bluk production

Production

confirm products specification again,then arrange the production

Order

Place order once you confirmed samples

Testing

Our QC team will be checked the products quality before delivery

Packing

packing products as required

Loading

Loading ready productsto client’s container

Receiving

Received you order

Why Choose Us

• 25 years exporting & 20 years manufacturing experience

• Factory covers an area of about 8000m²

• In 2021,all kinds of advanced production equipment had been replaced, including powder filling machine, pipe shrinking machine, pipe bending equipment, etc.,

• the average daily output is about 15000pcs

• Different Cooperative customer

• Customization depend on your requirement

Certificate

Related Products

Factory Picture

Before the inquiry,pls send us below specs:

1. Sending us the drawing or real picture;

2. Heater size,power and voltage;

3. Any special requirements of heater.

Contacts: Amiee Zhang

Email: info@benoelectric.com

Wechat: +86 15268490327

WhatsApp: +86 15268490327

Skype: amiee19940314