Product Configuration

Refrigeration double defrost heaters typically operate by means of electric heating. Specifically, when current passes through the resistance elements inside the heating tube, the resistance generates heat energy, causing the surface temperature of the heating tube to rise rapidly. Subsequently, this heat is transferred to the surface of the condenser through conduction, effectively melting the frost layer formed due to low-temperature conditions. This process not only restores the heat exchange efficiency of the condenser but also prevents performance degradation or system failures caused by frost accumulation.

The primary function of the double defrost heater tube is to prevent excessive frosting on the surface of cold storage units or refrigeration equipment. Frosting is a common occurrence in low-temperature environments, especially under high humidity conditions, where moisture in the air condenses and freezes on the surface of the condenser. If the frost layer becomes too thick, the double tube defrost heater significantly reduces the heat exchange efficiency of the condenser, thereby affecting the overall performance of the refrigeration system. Therefore, timely removal of the frost layer is crucial for maintaining the normal operation of the equipment.

In addition, the double defrost heater element also has a certain energy-saving effect. By regularly removing the frost layer, it can reduce the increased energy consumption of the refrigeration equipment due to the decrease in heat exchange efficiency, thereby achieving more efficient energy utilization.

Product Paramenters

| Porduct Name | Double Defrost Heater Element Tube for Unit Cooler Evaporator |

| Humidity State Insulation Resistance | ≥200MΩ |

| After Humid Heat Test Insulation Resistance | ≥30MΩ |

| Humidity State Leakage Current | ≤0.1mA |

| Surface Load | ≤3.5W/cm2 |

| Tube diameter | 6.5mm,8.0mm,10.7mm,etc. |

| Shape | straight,A-A type,U shape,W shape,etc. |

| Resistant voltage in water | 2,000V/min (normal water temperature) |

| Insulated resistance in water | 750MOhm |

| Use | Defrost Heater Element for unit cooler |

| Tube length | 300-7500mm |

| Lead wire length | 700-1000mm (custom) |

| Approvals | CE/ CQC |

| Company | Manufacturer/supplier/factory |

|

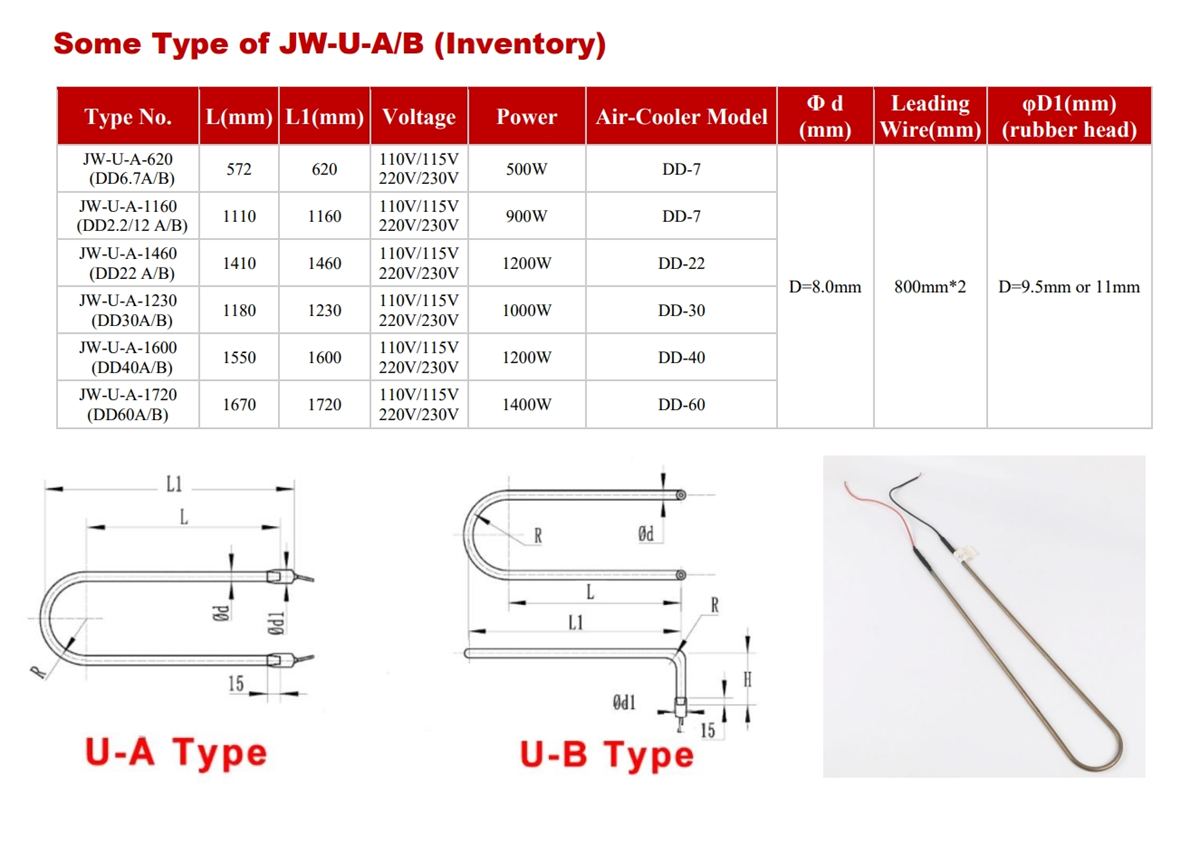

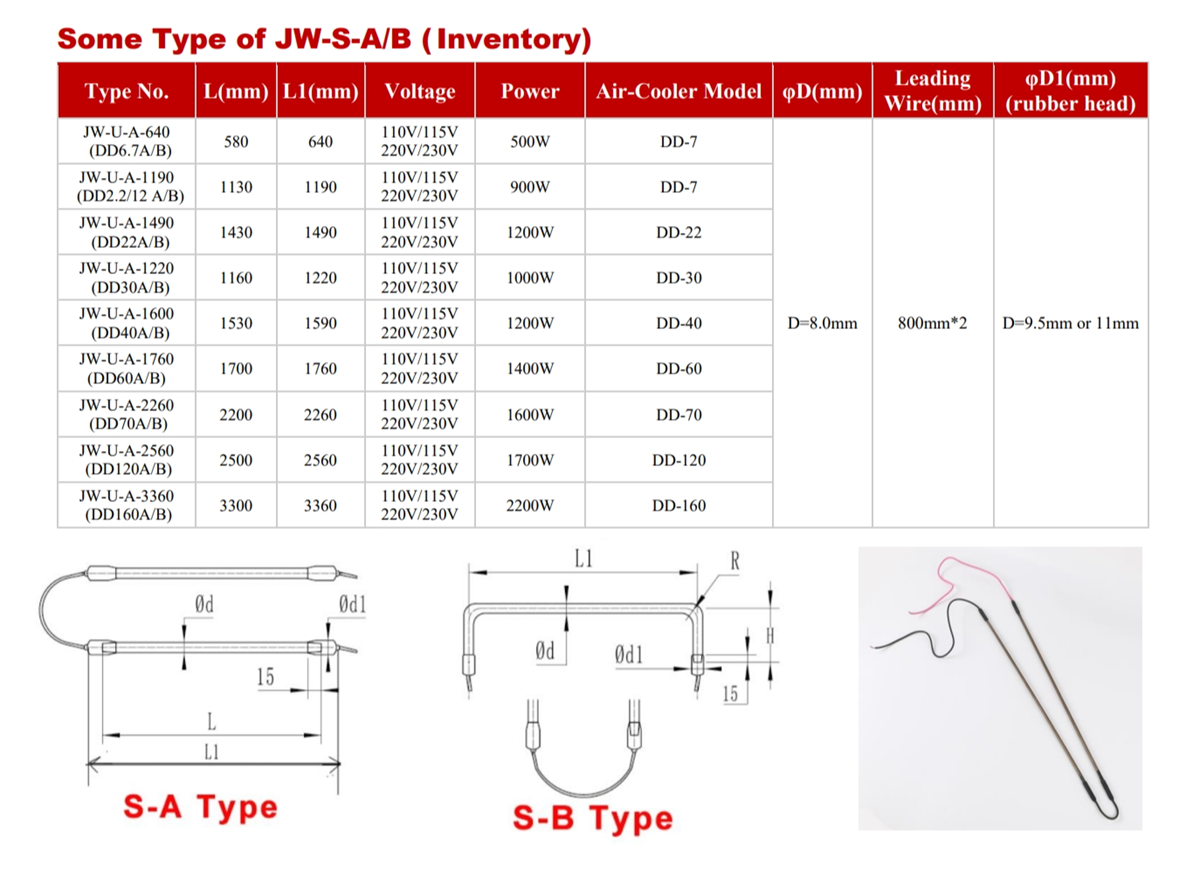

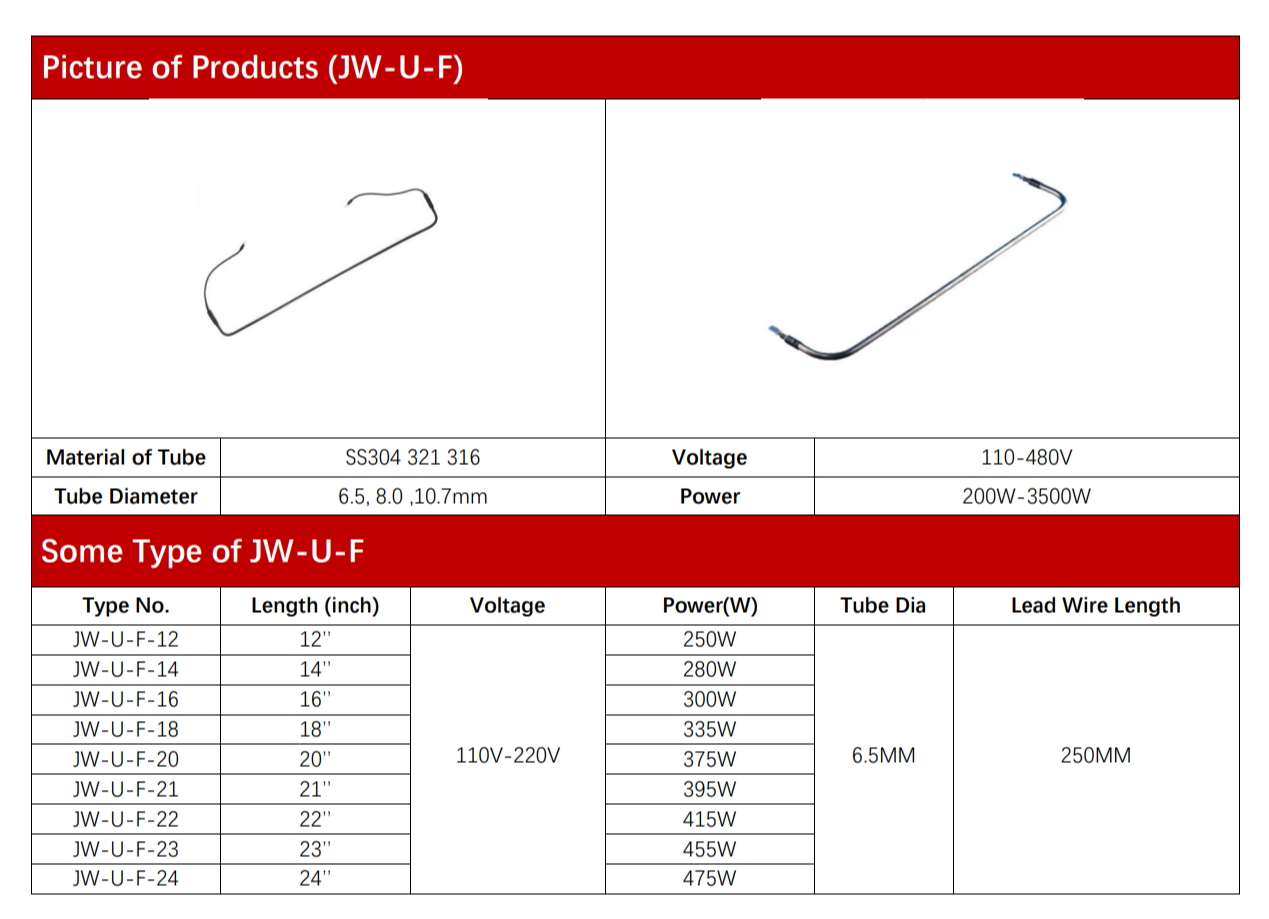

The double defrost heater is used for the air cooler defrosting,picture shape of defrost heating element is A-A type (double straight tube ),tube length custom is following your air-cooler size,our all defrost heater can be customized as required. The double defrost heater tube diameter can be made 6.5mm or 8.0mm,the tube with lead wire part will be sealed by rubber head.And the shape can also be made U shape and L shape.Power of defrost heating tube will be produced 300-400W per meter. |

|

Defrost Heater for Air-cooler Model

Singel Straight Defrost Heater

A-A Type Defrost Heater

U Shaped Defrost Heater

UB Shaped Defrost Heater

B Typed Defrost Heater

BB Typed Defrost Heater

Product Customized Design

To meet the demands of various application scenarios, the specifications of double tube defrost heaters can be customized based on actual conditions. For instance, in small household refrigerators, a low-power, small-sized heater may suffice; while in large industrial cold storage facilities, a higher-power, larger-area coverage heating device is required. Additionally, depending on the installation space and usage environment, different shapes of heating tubes (such as straight tubes, U-shaped tubes, etc.) and material types (such as stainless steel, copper, etc.) can be selected to adapt to specific working conditions.

Product Application

Refrigeration defrost heaters are one of the indispensable key components in modern refrigeration equipment and air conditioning systems. Their core function is to provide additional heat to melt the frost formed on the surface of the condenser, thereby ensuring the efficient operation of the entire refrigeration system. In practical applications, this double defrost heater is widely used in cold storage rooms, refrigerators, air conditioners, and other scenarios that require low-temperature environments.

Production Process

Service

Develop

received the products specs,drawing,and picture

Quotes

the manager feedback the inquiry in 1-2hours and send quotation

Samples

Free samples will be sent for check products quality before bluk production

Production

confirm products specification again,then arrange the production

Order

Place order once you confirmed samples

Testing

Our QC team will be checked the products quality before delivery

Packing

packing products as required

Loading

Loading ready productsto client’s container

Receiving

Received you order

Why Choose Us

• 25 years exporting & 20 years manufacturing experience

• Factory covers an area of about 8000m²

• In 2021,all kinds of advanced production equipment had been replaced, including powder filling machine, pipe shrinking machine, pipe bending equipment, etc.,

• the average daily output is about 15000pcs

• Different Cooperative customer

• Customization depend on your requirement

Certificate

Related Products

Factory Picture

Before the inquiry,pls send us below specs:

1. Sending us the drawing or real picture;

2. Heater size,power and voltage;

3. Any special requirements of heater.

Contacts: Amiee Zhang

Email: info@benoelectric.com

Wechat: +86 15268490327

WhatsApp: +86 15268490327

Skype: amiee19940314