Product Configuration

The bake oven coil heating element is a special type of dry-burning heating tube designed for high-temperature environments. The dry-burning electric heating tube refers to an electric heating tube that operates directly exposed to the air without coming into contact with liquid.The design of oven coil heating element enables it to run stably for a long time under high-temperature conditions while avoiding corrosion or damage caused by liquid media.

From the perspective of internal structure, the core part of the oven coil heating element is composed of heating wires arranged in a spiral pattern. This spiral structure not only ensures uniform heat release but also significantly enhances the overall mechanical strength of the element. Even under conditions of high-frequency vibration or extreme temperature changes, the heating wires are less likely to break or fail. Moreover, due to the use of high-temperature resistant and anti-oxidation materials, the average service life of such heating elements can reach over 3000 hours, making them highly suitable for household or commercial oven equipment that requires long-term stable operation.

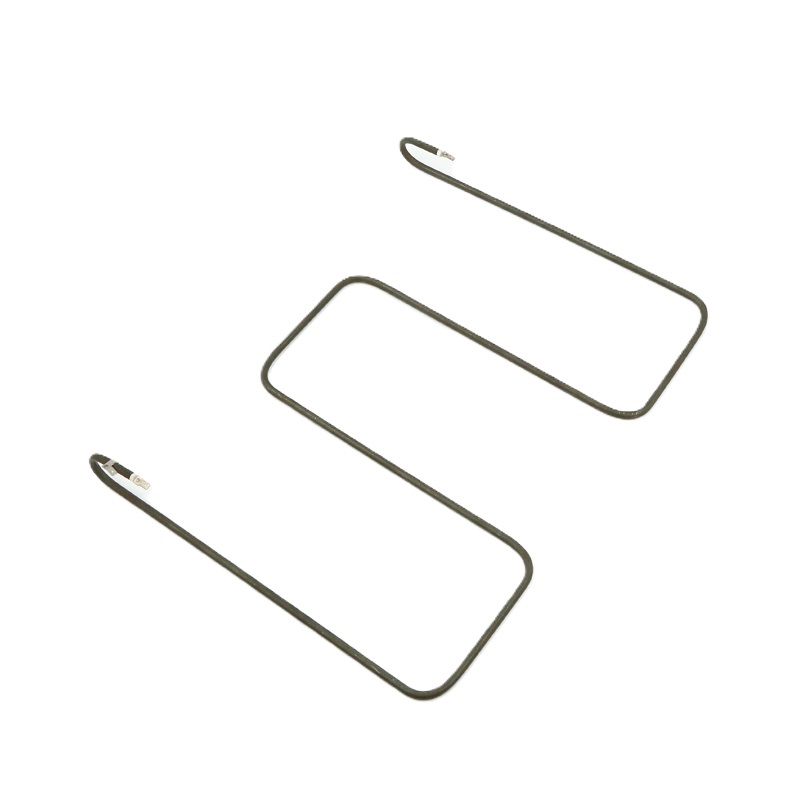

From the perspective of appearance, the resistance part of the bake oven coil heating element in an stove is usually made of specially treated deep green stainless steel. This stainless steel surface is given a unique deep green color through a "annealed" process. Therefore, when we open an oven in our daily life, we will find that the internal heating tubes are deep green instead of the dull color that ordinary metals turn after oxidation. This feature not only enhances the aesthetic appeal but also indicates that the material has excellent anti-oxidation properties, which can effectively extend the service life of the oven coil heating element.

Product Paramenters

| Porduct Name | Bake Element Replacement Parts Electric Oven Coil Heating Element |

| Humidity State Insulation Resistance | ≥200MΩ |

| After Humid Heat Test Insulation Resistance | ≥30MΩ |

| Humidity State Leakage Current | ≤0.1mA |

| Surface Load | ≤3.5W/cm2 |

| Tube diameter | 6.5mm,8.0mm,10.7mm,etc. |

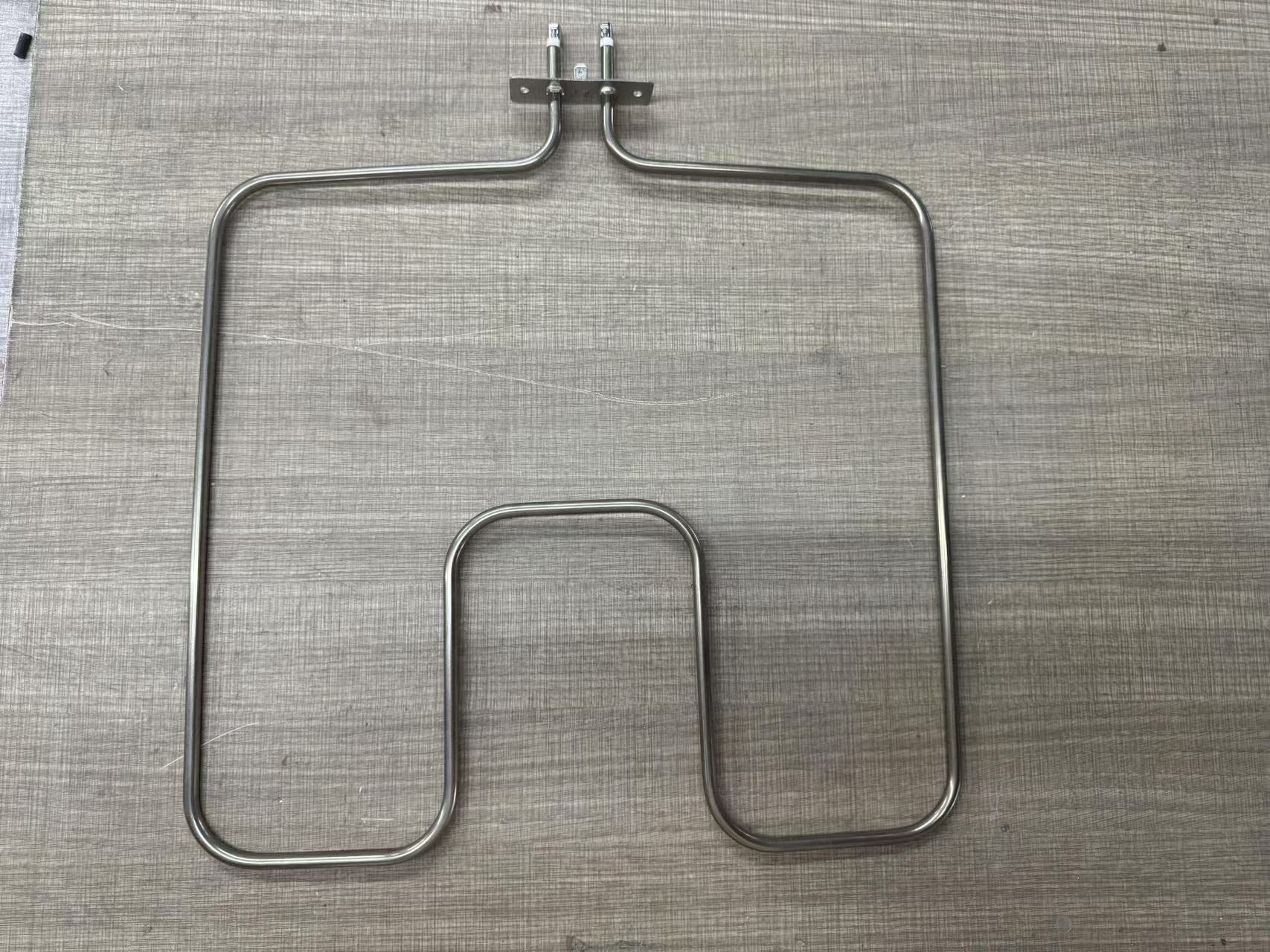

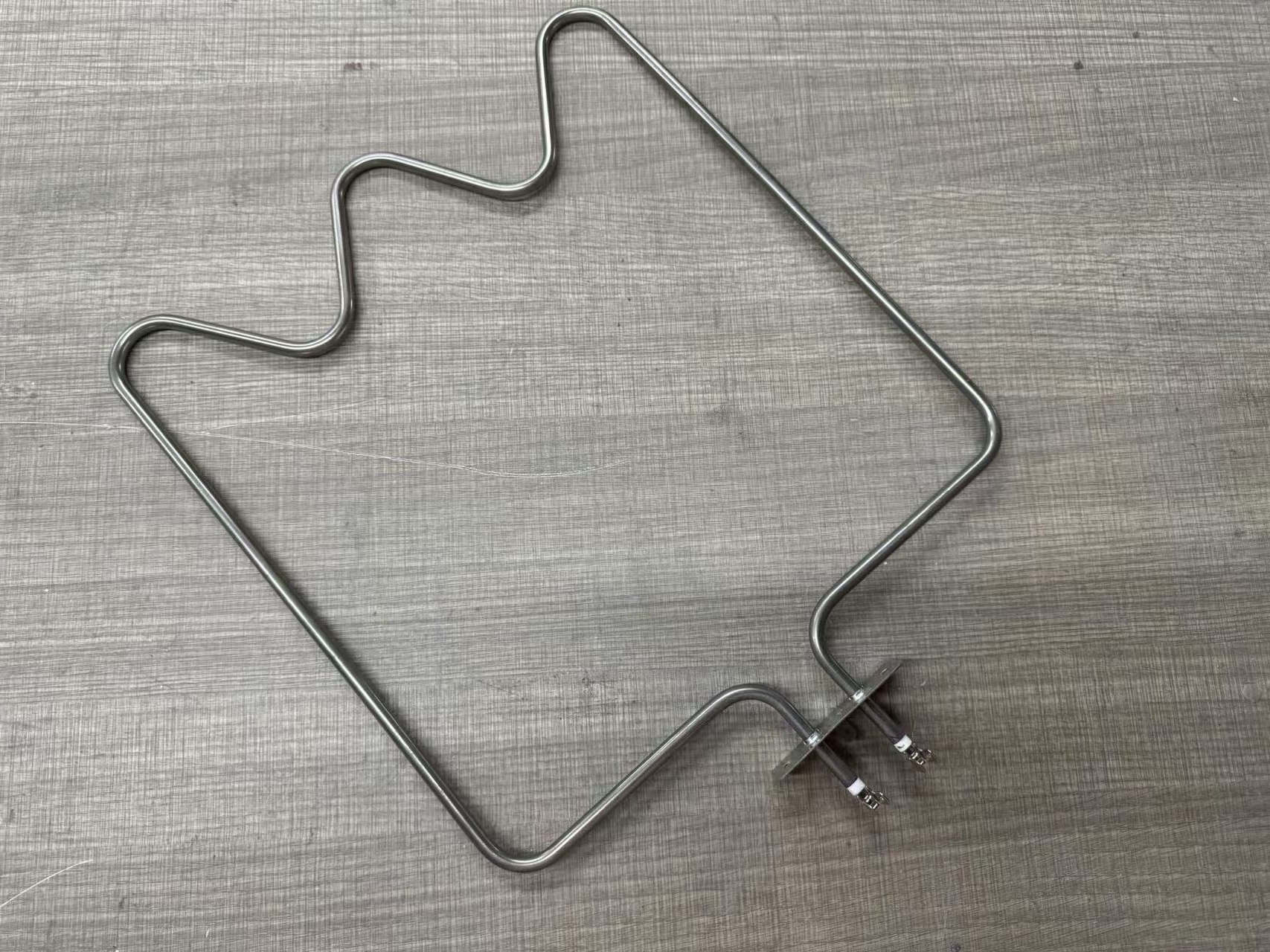

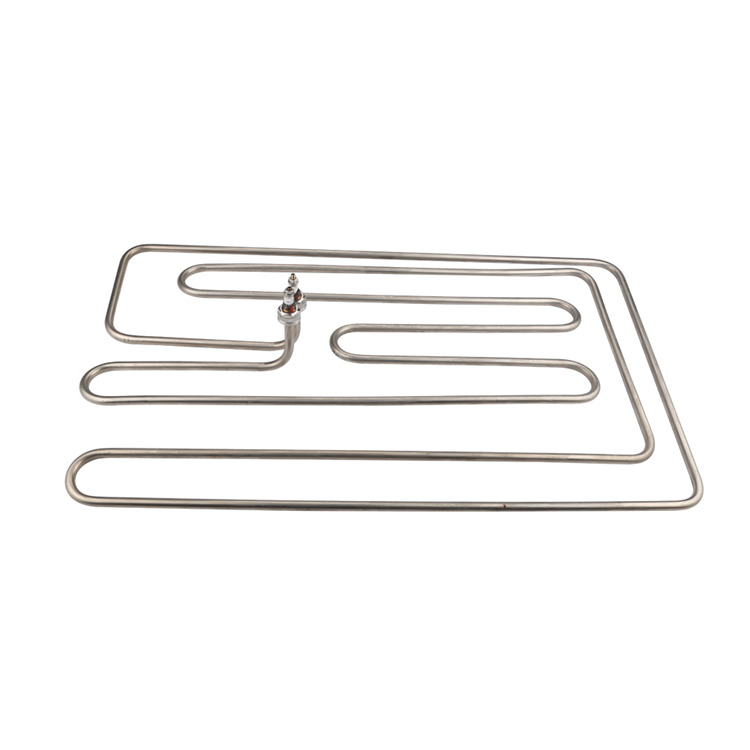

| Shape | straight,U shape,W shape,etc. |

| Resistant voltage | 2,000V/min |

| Insulated resistance in water | 750MOhm |

| Use | Oven Coil Heating Element |

| Tube length | 300-7500mm |

| Shape | customized |

| Approvals | CE/ CQC |

| Company | factory/supplier/manufacturer |

|

The tubular oven coil heating element heater is used for the microwave,stove,electric grill.Shape of the oven heater tube can be customized as client’s drawings or samples.The tube diameter can be choosed 6.5mm,8.0mm or 10.7mm. JINGWEI HEATER is the professional heating tube factory/supplier/manufacturer,the voltage and power of oven heating element for grill/stove/microwave can be customized as required.And the oven heating element tube can be annealed,the tube color will be dark green after annealing.We have many kinds of the terminal models,if you need add the terminal,you need send us the model number first. |

|

Products Features

These different shape designs aim to optimize heat distribution and adapt to the requirements of various oven internal structures. For instance, the U-shaped and W-shaped designs can increase the effective length of the heating wire to enhance the heat output efficiency per unit area, thereby achieving a more uniform heating effect.

Products Appliance

Oven coil heating elements are crucial components in both residential and industrial settings, responsible for generating the heat needed for cooking, baking, and various industrial processes. In residential ovens, the bake oven coil heating elements are typically found as bake (bottom) and broil (top) elements, with convection ovens also incorporating a fan and heating element for even heat distribution.

JINGWEI Workshop

Production Process

Service

Develop

received the products specs,drawing,and picture

Quotes

the manager feedback the inquiry in 1-2hours and send quotation

Samples

Free samples will be sent for check products quality before bluk production

Production

confirm products specification again,then arrange the production

Order

Place order once you confirmed samples

Testing

Our QC team will be checked the products quality before delivery

Packing

packing products as required

Loading

Loading ready productsto client’s container

Receiving

Received you order

Why Choose Us

• 25 years exporting & 20 years manufacturing experience

• Factory covers an area of about 8000m²

• In 2021,all kinds of advanced production equipment had been replaced, including powder filling machine, pipe shrinking machine, pipe bending equipment, etc.,

• the average daily output is about 15000pcs

• Different Cooperative customer

• Customization depend on your requirement

Certificate

Related Products

Factory Picture

Before the inquiry,pls send us below specs:

1. Sending us the drawing or real picture;

2. Heater size,power and voltage;

3. Any special requirements of heater.

Contacts: Amiee Zhang

Email: info@benoelectric.com

Wechat: +86 15268490327

WhatsApp: +86 15268490327

Skype: amiee19940314