Product Configuration

The silicone rubber heating wire for defrosting is an electric heating element with high-performance silicone rubber as the insulating material. The silicone rubber heating wire for defrosting core structure, from the inside out, consists of a glass fiber core, resistance alloy wire (such as nichrome or copper-nickel wire) wound around it, and a tightly wrapped silicone rubber insulating layer. This composite structure not only endows the heating wire with excellent thermal conductivity and electrical insulation, but also gives it outstanding flexibility and mechanical strength, enabling it to adapt to complex installation environments and operate stably for a long time.

The outer diameter of the silicone rubber heating wire for defrost ranges widely from φ1.2mm to φ6.0mm, suitable for various application scenarios with different space limitations. Its resistance value can be customized according to requirements, with a resistance range of 0.3 to 20,000 ohms/meter, enabling precise control of heating power. This defrost silicone rubber heating wire can operate normally under extreme temperature conditions, with a temperature resistance range of -70℃ to +200℃, ensuring good performance even in extremely cold environments. In terms of output power, it can reach up to 40-60W/m, meeting the demand for efficient heating; at the same time, it supports a maximum working voltage of 600V, suitable for various power supply systems.

Product Paramenters

| Porduct Name | 3.0mm Silicone Rubber Heating Wire Cable for Defrosting |

| Insulation Material | Silicone rubber |

| Wire diameter | 2.5mm,3.0mm,4.0mm,etc. |

| Heating length | customized |

| Lead wire length | 1000mm,or custom |

| Color | white,grey,red,blue,etc. |

| MOQ | 100pcs |

| Resistant voltage in water | 2,000V/min (normal water temperature) |

| Insulated resistance in water | 750MOhm |

| Use | defrost door heating wire |

| Certification | CE |

| Package | one heater with one bag |

|

The 3.0mm silicone rubber heating wire for defrost length,voltage and power can be customized as required.The wire diameter can be choosed 2.5mm,3.0mm,3.5mm,and 4.0mm.The wire surface can be braided firberglass,aluminum or stainless steel. The silicone rubber door frame heating cable heating part with lead wire connector can be seal with rubber head or double-wall shrinkable tube,you can choose according to your own use needs. |

|

Product Features

Safe and reliable

*** Flame retardant silicone material Double layer insulation, eliminating the risk of leakage or fire.

Energy-efficient

*** The three-dimensional braided heating wire structure has high thermal efficiency, which is 45% energy-saving compared with the traditional heating line.

*** Carbon fiber models (some alternatives) have fast heating up from far-infrared radiation and energy saving of 30%.

Adaptable

*** Flexible and easy to bend, it fits complex curved surfaces (e.g. pipes, car cushions).

*** Corrosion-resistant, anti-aging, suitable for humid and chemically corrosive environments (such as cold storage, chemical pipelines).

Product Application

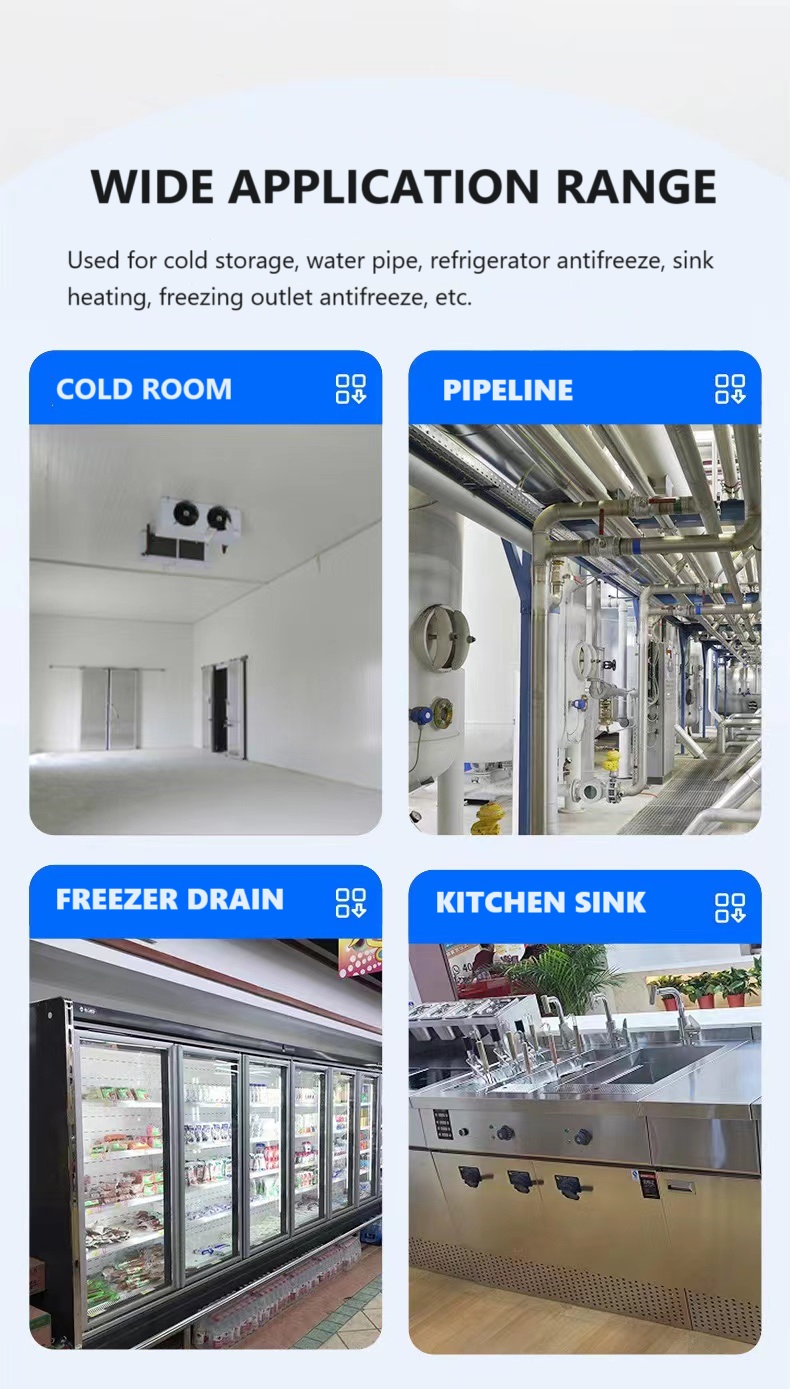

Due to its outstanding performance, silicone rubber defrosting heating wire is widely used in various fields.

In the home appliance industry, the silicone rubber heating cable is mainly used for defrosting heating in refrigerators, air conditioners and freezers, effectively preventing frost formation on the evaporator surface and affecting the cooling efficiency.

In cold chain logistics and freezing equipment, silicone rubber door frame heating wire can be used for anti-icing of fans and thawing of drain pipes in cold storage, avoiding equipment damage or operational failure caused by ice formation.

Additionally,the silicone rubber heating wire can also be used in drain pipe anti-freezing systems to ensure the unobstructed operation of the drainage system in low-temperature environments.

In the automotive industry, this heating wire is also applied to window heating devices, enhancing the comfort and safety of vehicles in cold climates.

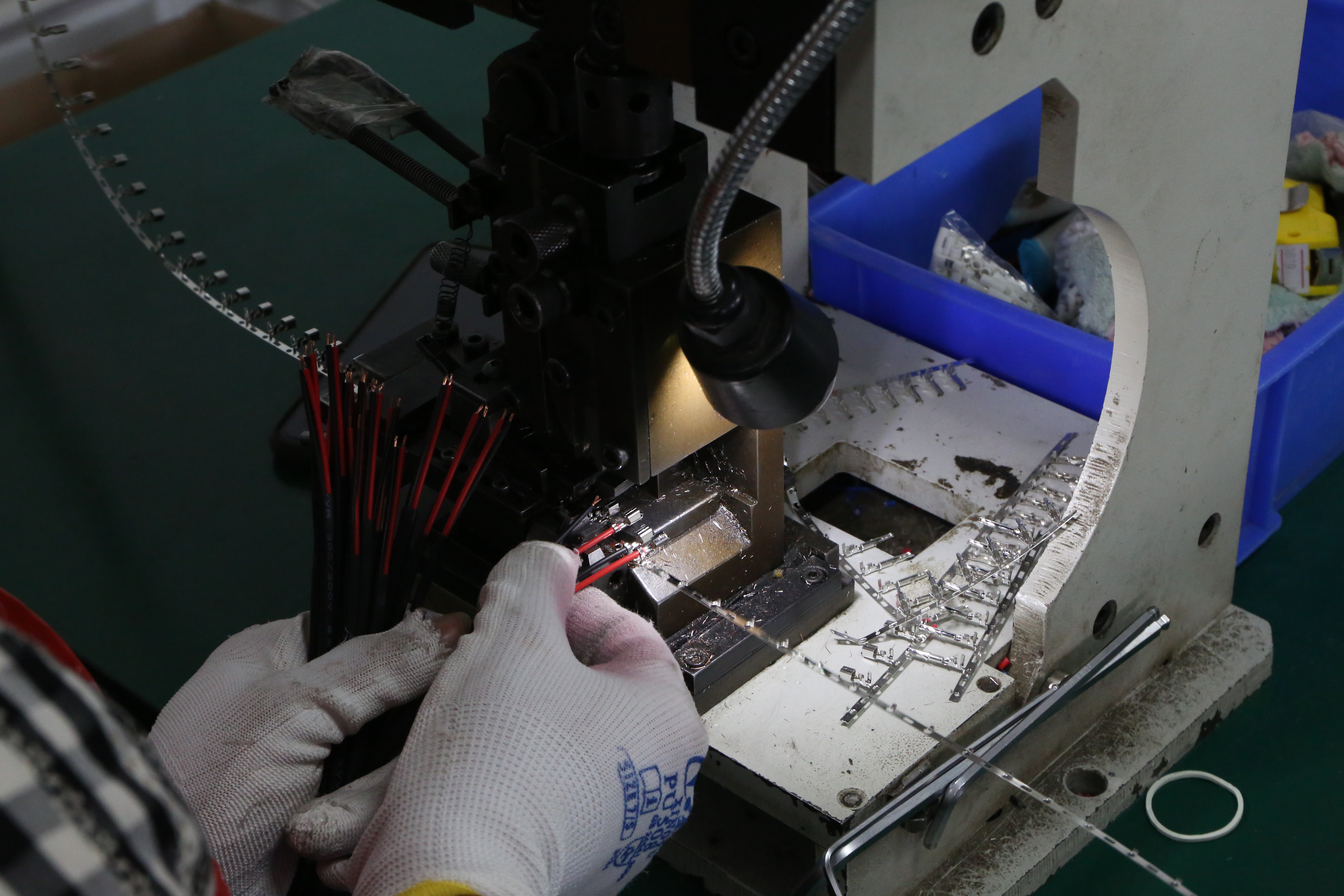

Factory Picture

Production Process

Service

Develop

received the products specs,drawing,and picture

Quotes

the manager feedback the inquiry in 1-2hours and send quotation

Samples

Free samples will be sent for check products quality before bluk production

Production

confirm products specification again,then arrange the production

Order

Place order once you confirmed samples

Testing

Our QC team will be checked the products quality before delivery

Packing

packing products as required

Loading

Loading ready productsto client’s container

Receiving

Received you order

Why Choose Us

• 25 years exporting & 20 years manufacturing experience

• Factory covers an area of about 8000m²

• In 2021,all kinds of advanced production equipment had been replaced, including powder filling machine, pipe shrinking machine, pipe bending equipment, etc.,

• the average daily output is about 15000pcs

• Different Cooperative customer

• Customization depend on your requirement

Certificate

Related Products

Factory Picture

Before the inquiry,pls send us below specs:

1. Sending us the drawing or real picture;

2. Heater size,power and voltage;

3. Any special requirements of heater.

Contacts: Amiee Zhang

Email: info@benoelectric.com

Wechat: +86 15268490327

WhatsApp: +86 15268490327

Skype: amiee19940314