The defrost heater heating tube is an indispensable key component in refrigeration equipment. The main function of defrost heater is to remove the ice and frost formed inside the refrigeration equipment due to the low-temperature environment by heating. This process can not only restore the cooling efficiency of the equipment, but also effectively protect the equipment from damage caused by the accumulation of ice and frost. The following will elaborate in detail from four aspects: the function, working principle, application in the refrigeration system and its importance of the defrost heater heating tube.

I. The Function of Defrost Heater Heating tubes

During the operation of refrigeration equipment, due to the low temperature, a layer of ice and frost is prone to form on the surface of the equipment, especially in the evaporator area. This layer of frost will impede the circulation of cold air, reduce the cooling efficiency, and may even cause physical damage to the equipment. To solve this problem, defrost heating tubes came into being. It releases heat to quickly melt the frost on the surface of the equipment, thereby restoring the normal working state of the refrigeration equipment. For instance, in a household refrigerator, if too much frost accumulates on the evaporator, it will cause the temperature inside the freezer compartment to fail to reach the set value, affecting the preservation effect of food. At this point, the defrosting heating tube can function promptly to ensure the continuous and efficient operation of the equipment.

Ii. Working Principle of Defrost Heating Tubes

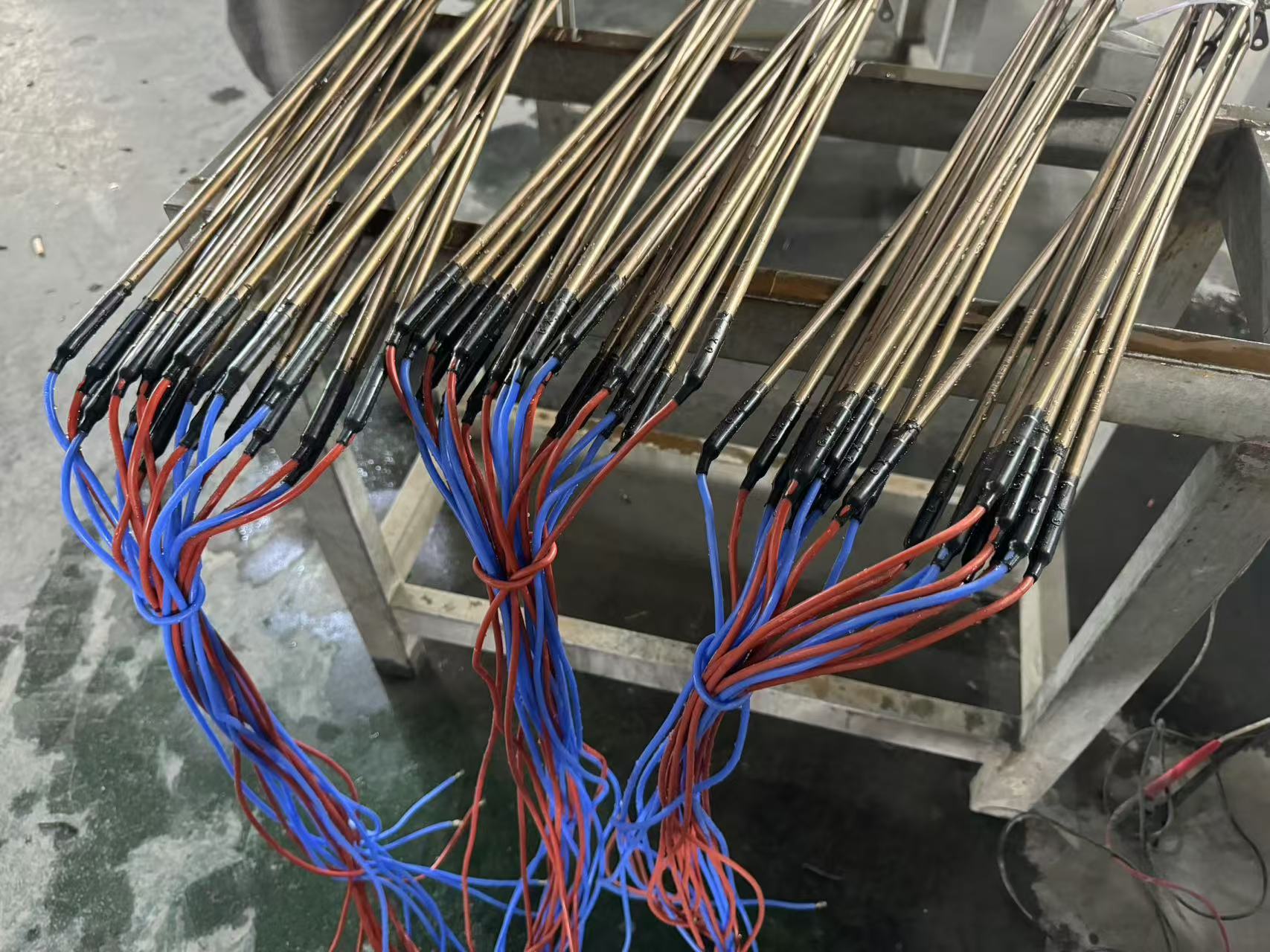

The working principle of the defrosting heater heating tube is based on the electrothermal conversion technology. Its core component is the electric heating wire, which is a material capable of efficiently converting electrical energy into thermal energy. When the refrigeration equipment needs to undergo defrosting operation, the control system will send a start signal to the defrosting heater tube. Subsequently, an electric current passes through the heating wire, causing it to heat up rapidly and generate heat. This heat is transferred to the surface of the equipment, causing the frost to gradually melt into water. The melted water is then discharged through the built-in drainage system of the equipment to prevent accumulation inside the equipment, thus keeping it clean and dry.

In addition, the design of modern defrost heating tubes also focuses on energy conservation and safety. For instance, many products use ceramic insulating materials to wrap the heating wires, which not only enhances the heat conduction efficiency but also improves safety, preventing accidental damage caused by overheating. Meanwhile, some high-end devices are also equipped with temperature sensors, which can monitor the working temperature of the defrosting heater tubes in real time, ensuring that they operate within a reasonable range and further enhancing the reliability and service life of the equipment.

Iii. Application of Defrost Heating Tubes in Refrigeration Systems

Defrosting heater tubes are widely used in various refrigeration equipment, including but not limited to household refrigerators, commercial freezers, central air conditioners, etc. Among these devices, defrost heating tubes are usually installed near the evaporator or condenser to function quickly when needed. Take commercial refrigerators as an example. Due to their large storage capacity and high usage frequency, the rate at which frost accumulates is often faster. Therefore, it is particularly important to be equipped with highly efficient defrosting heating tubes, which can significantly reduce the problem of decreased refrigeration efficiency caused by untimely defrosting.

With the advancement of technology, an increasing number of refrigeration equipment have begun to adopt intelligent control systems to manage the operation of defrosting heating tubes. For instance, some high-end refrigerators can automatically determine whether to start the defrosting program through their built-in humidity and temperature sensors, and adjust the working time and power of the defrosting heating tubes according to the actual situation. This intelligent design not only enhances the defrosting effect but also effectively reduces energy consumption, providing users with a more convenient and economical usage experience.

Iv. The Importance of Defrosting Heating Tubes

Defrosting heater heating tubes play an irreplaceable and significant role in the normal operation of refrigeration equipment. First of all, it can effectively remove ice and frost, ensuring the refrigeration efficiency of the refrigeration equipment. Secondly, by regularly removing frost and ice, the defrosting heating tube can also extend the service life of the equipment and reduce maintenance costs. If the refrigeration equipment lacks defrosting heating tubes or their functions malfunction, ice and frost may accumulate continuously, eventually causing the equipment to fail to operate normally. For instance, in an air conditioning system, if the frost on the evaporator is not removed in time, it may clog the air passage, affect the indoor temperature regulation effect, and even cause the compressor to overload and get damaged.

Therefore, when using refrigeration equipment in daily life, users should regularly check the working condition of the defrosting heating tubes to ensure their normal operation. For instance, one can determine whether the defrosting heating tube is in good condition by observing whether there is any abnormal accumulation of ice and frost on the surface of the equipment or by listening for any obvious heating sounds during the defrosting process. Once any problem is found, professional technicians should be contacted in time for maintenance to avoid affecting the overall performance of the equipment.

Summary

In conclusion, the defrosting heating tube, as a key component in refrigeration equipment, plays a crucial role. It can not only remove ice and frost by heating to ensure the refrigeration efficiency, but also effectively protect the equipment from damage caused by ice and frost accumulation. With the continuous development of technology, future defrosting heating tubes are expected to adopt more advanced technologies and materials, further enhancing their working efficiency and energy-saving performance. For instance, the application of new nanomaterials may endow defrosting heating tubes with higher thermal conduction efficiency, while the upgrade of the intelligent control system can enable them to adapt more precisely to different usage scenarios. These improvements will provide users with more efficient and reliable refrigeration solutions, bringing more convenience and comfort to daily life.

Post time: May-02-2025